How to Use the PA-04/H Automatic Feeder for Tablet Weight Uniformity Control?

The PA-04/H automatic feeder manufactured by RADWAG is a versatile device that is widely used in various branches, especially in the pharmaceutical industry. One of the many uses of the feeder in this area is, described in this article, the control of tablet weight uniformity.

What Is the Optimization of the Tabletting Process?

Tablet production is a complex process with a fairly high level of risk, in which quality must be constantly maintained at a high level. The tabletting technologies used today ensure maximum efficiency of the process line while maintaining the relevant properties of the medical formulation. The key to achieving and maintaining both is to optimize the tabletting process taking into account the specific characteristics of the tablet such as size, composition, drug release rate and the capabilities and limitations of the tabletting system. An important parameter of any tablet is its weight, which is de facto the sum of all the components that make up its matrix.

What Are the Popular Types of Tablets?

One of the popular types of tablets today are polymeric matrix tablets with a controlled release rate of the drug substance. In this solution, the drug release rate can be modified by additives such as, for example, hypromellose (a semi-synthetic cellulose derivative, HPMC), which can account for about 20-40% of the tablet weight. Another novel tablet form is tablets that disintegrate in the mouth referred to as Oro-Dispersible Tablets (ODTs). The small size of ODTs and the rapid disintegration of the drug in the patient’s mouth (about 30 seconds) is an excellent example of personalization in medicine dedicated to pediatric and geriatric patients and in cases of dysphagia. From a medical point of view, the speed of ODT is important, desirable in cases of migraine, severe pain or diarrhea.

Why Is It Important to Control the Tablet Weight Uniformity?

Regardless of the type of tablet, the weight of each tablet must be within certain limits. On the one hand, tablet weight uniformity in a production run is a normative requirement that must be taken into account for a production run to be considered compliant. On the other hand, tablet weight drifts observed in a production batch are an indicator for process control, where uniformity of filling the tablet die cavity is important. This is a complex process whose efficiency depends on the flowability, cohesion and particle size of the powder mixture. This means that the tablet weight can be considered a quality indicator of the tabletting process. Usually the weight is measured manually, but as is well known, this process is sometimes subject to reading, writing or calculation error. For this reason, automation is increasingly being introduced, which, on the one hand, reduces the possibility of error and, on the other hand, reduces the time required to perform the test.

Tablet Weight Uniformity Control – Manual vs. Automatic Methods

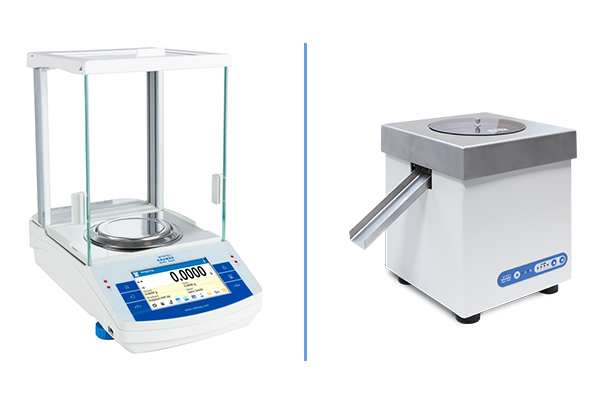

In the comparative study, the tablet weight uniformity was determined using the manual and automatic methods. In the manual method, each tablet was manually fed with tweezers by the operator onto the pan of an AS 220.X2 PLUS analytical balance. In the second method, an PA-04/H automatic feeder was used, in which, as a result of vibration, successive tablets were automatically moved through a special drain chute onto the balance pan of the AS 220.X2 PLUS. There were no significant differences in weight measurements performed by the manual and automatic methods. All tablets tested met the US Pharmacopeia (USP) requirements for their weight uniformity. The differences in the accuracy and precision of weight measurements of the automatic and manual methods were not statistically significant. The two methods for testing tablet weight uniformity can be used interchangeably, as chosen by the analysts conducting the study in this area.

More details on this issue can be found in the publication, one of the authors of which is the head of the Research Laboratory at the RADWAG Research and Certification Metrology Centre, Slawomir Janas, PhD.