Do All Weighing Instruments Have to Be Verified? Verification as a Legal Obligation Regarding Electronic Balances

Balance verification is a legal act, it constitutes state supervision over a measuring device and concerns weighing instruments used in specific areas. Which exactly? Read the article to find out. We are providing answers regarding balance verification, we tell when it is required, what is the metrological importance of verification and does verification impose limitations on balance functionality.

When Is Balance Verification Required?

Your weighing instrument must be verified if it is operated in one of the following areas:

- health, life and environment protection,

- public safety and order,

- consumer rights protection,

- collection of fees, taxes, other receivables; determination of discounts, contractual fines, wages and compensation; collection and determination of dues and benefits,

- customs control,

- public trading.

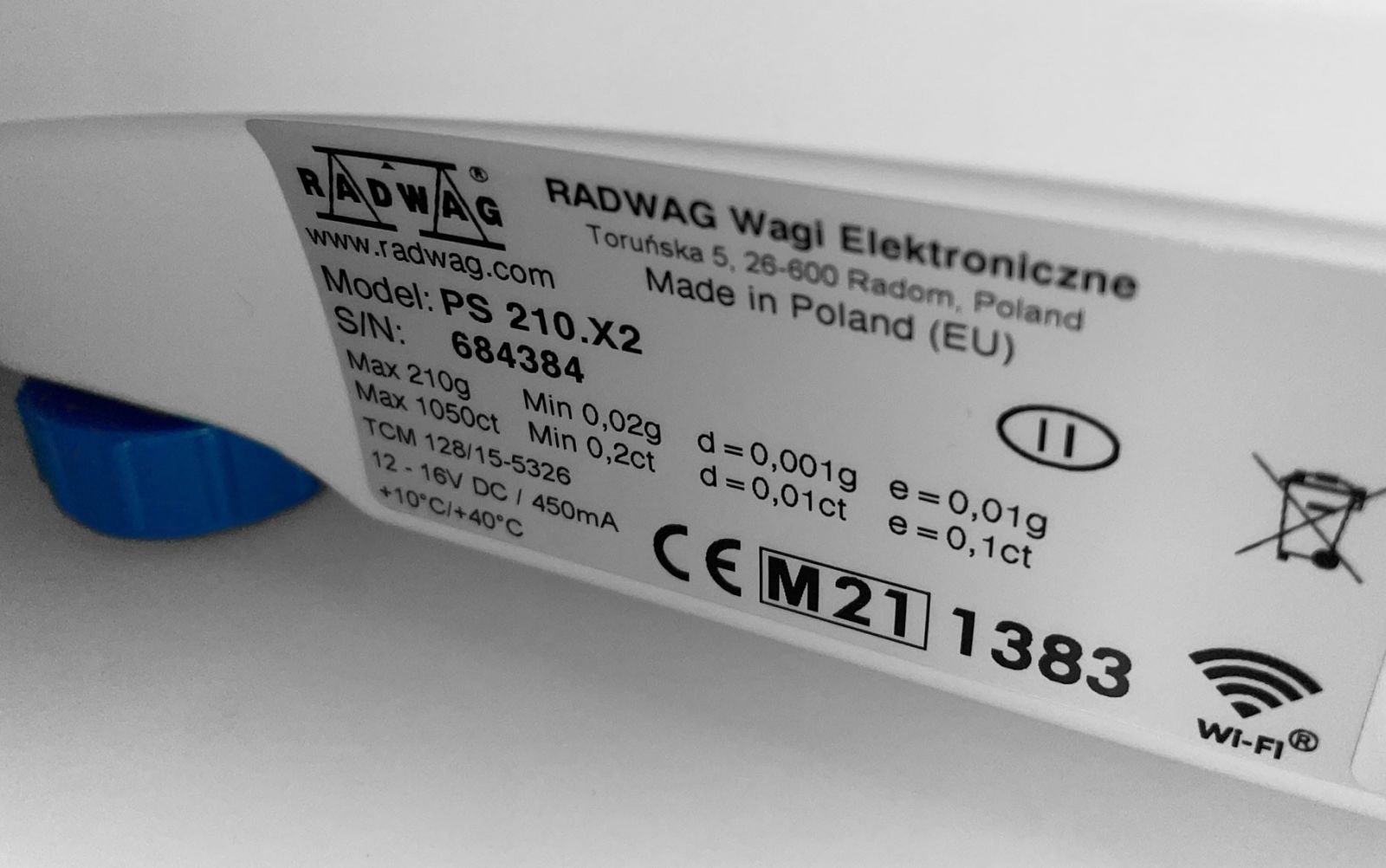

With regard to this, it may be concluded that it depends on the balance application, more precisely on the area of its use, whether the given device must be verified or not. This information is a commonly known fact, however, sometimes it is totally neglected by the users. Radwag used to sell only verified balances, which was a consequence of regulations valid prior 2004. While manufacturing our products we do not distinguish between the verified and non-verified weighing instruments, all devices are a subject to the same metrological requirements. Our quality system, ISO 9001, subjected to regular audits, enables us to self-assess the conformity, therefore all the balances and scales we produce are verified, however you do not have to take advantage of it in a legal sense. In practice it means that after verification validity end, you are not obliged to subject your device to a subsequent verification if the said device is not operated in the above specified areas.

Metrological Importance of Verification

As it has been already mentioned, verification is a state supervision over the measuring instrument, therefore, in order to assess the given device, relevant legal regulations are applied. A proper document in the case of weighing instruments is PN-EN 45501 standard. It regulates many issues, the most important are balance maximum permissible errors. In the course of verification, the whole weighing range is tested and the size of maximum permissible errors evaluated. The subsequent verification aims to check if the device complies with the specified requirements. Unfortunately, balance deviations (errors) are not provided so the user receives no information specifying whether weighing of, for example, 2 000 g load is burdened with an error or not. Maximum permissible errors of a balance in the course of verification are to be found in the below table. Balance parameters:

- Max 6 000 g

- d = 0.01 g

- e = 0.1 g

|

Load |

PN-EN 45501 |

Verification |

In-Use |

Manufacturer’s Declaration |

|

0-500 g |

0.5 e |

0.05 g |

0.10 g |

0.03 g |

|

500 g-2 000 g |

1.0 e |

0.10 g |

0.15 g |

0.03 g |

|

2 000 d-6 000 g |

1.5 e |

0.15 g |

0.30 g |

0.03 g |

Even rough analysis clearly shows that the subsequent verification performed by a respective body can be carried out for a balance with significant indication errors, therefore this procedure provides no information about the very measurement itself. It only informs that balance errors are not greater than those given in column 3.

Verification and Balance Functionality

Balance verification to some extent limits flexibility when it comes to balance use. Periodical adjustments are required. Adjustment often activates in the least favourable time. In the case of a NON-VERIFIED balance it is up to you when and how the adjustment is to be carried out. It may be:

- internal adjustment,

- adjustment performed using an external mass standard,

- adjustment performed using a mass standard of any weight value.

Automatic adjustment can be turned off if there is such a need. This enables you to adapt the balance to your current requirements. Lack of verification in the case of Radwag balances DOES NOT MEAN poor quality – the quality of all our balances is the same regardless of the fact whether they are provided with a verification mark or not.

Weighing Instrument Verification – Summary

If there is no legal requirement for use of a verified balance then it is reasonable to take a non-verified one. In the case of Radwag products, all our devices are a subject to the same criteria regardless of their area of use. It is commonly believed that a verified balance is better than the non-verified instrument since it has a certificate (type approval) confirmed by a notified body. However, indication errors declared by the manufacturer are often significantly lower than the legally permissible errors. Information about balance errors can be obtained only via balance calibration, which is crucial for all those who perform the measurements. It is assumed that calibration is carried out by an accredited laboratory.

Should you have any questions regarding balance verification, or look for information about verified weighing instruments from RADWAG product range, write to our expert: