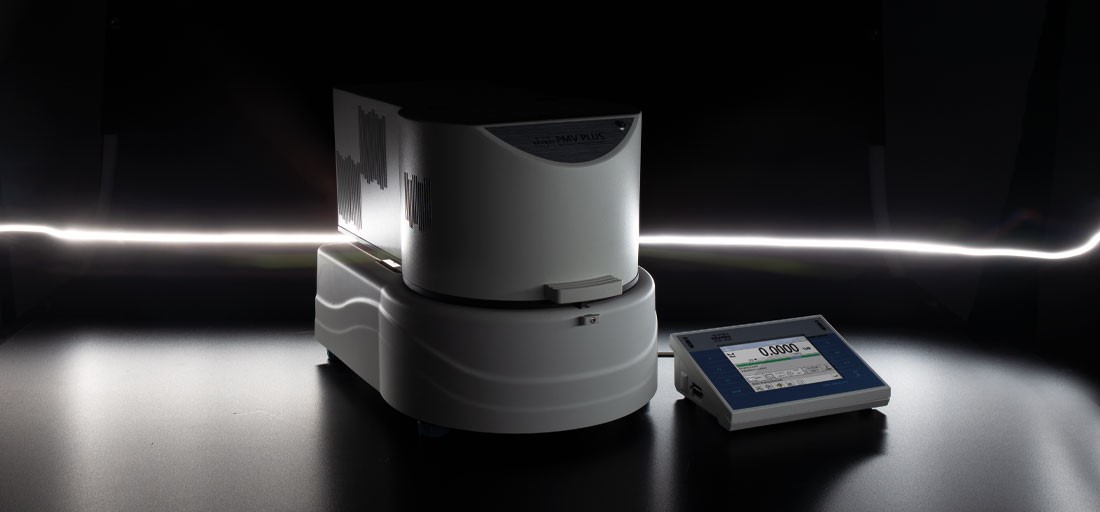

Why the PMV 50 PLUS Microwave Moisture Analyzer by RADWAG? The Fastest and Extremely Accurate Method of Water Content Determination

With top speed and best accuracy - that's the way the PMV 50 PLUS RADWAG moisture analyzer determines water content. This new product in our range guarantees the shortest drying time and the best measurement accuracy at the same moment. Before we answer questions regarding other benefits of using the PMV 50 PLUS moisture analyzer and what its application is, we will explain what is it used for and how it works.

What Is the Intended Use of the PMV 50 PLUS Microwave Moisture Analyzer by RADWAG?

The PMV 50 PLUS microwave moisture analyzer is intended for measurement of sample moisture content ranging between 0.001 and 100%. Drying is carried out by means of microwaves, which use the dipole movement of water molecules in the product structure. It is for this reason that the drying time is much shorter than with moisture analyzers that use regular radiation and convection.

How Does the PMV 50 PLUS Microwave Moisture Analyzer by RADWAG Work?

Operation of the PMV 50 PLUS microwave moisture analyzer is very easy. Simply place the sample in the drying chamber on the glass fibre filter. At the bottom of the chamber there is one end of the waveguide from where the microwaves are emitted. Activation of the moisture analyzer causes a uniform movement of microwaves, which generate vibrations of water molecules, resulting in water evaporation and leading to sample drying. The loss of mass recorded during this process informs you of the water content of the sample or its dry mass content.

The drying profile shall be selected in accordance with the sample properties. There are four drying programs: standard, mild, step, fast. They differ by the dynamics of temperature increase.

The PMV 50 PLUS RADWAG Microwave Moisture Analyzer - Functions, Features and Benefits

"High accuracy, four drying programs and drying process visualisation" - it all sounds very well and is true, but what do you get out of it? In order to fully understand and appreciate the features and functions offered by the PMV 50 PLUS microwave moisture analyzer, we have prepared a table in which we translate them into the language of benefits:

|

Feature/ Function |

Benefit |

|

Microwave solution |

Extremely short drying time (approx. 3 minutes) |

|

Readability: 0.1 mg |

Very accurate mass measurement |

|

Moisture content readability: 0.0001% |

Very accurate moisture content measurement |

|

Range of moisture content readout: 8-100% |

Wide spectrum of moisture content measurement |

|

4 drying programs |

Accurate readout within optimal time |

|

Memory: 32 GB |

Complex databases |

|

Wireless communication |

Improved ergonomics and safety of operation |

|

Wi-Fi® |

Sending data between the moisture analyzer |

|

Large 5.7’’ display with touch screen |

More comfortable operation |

|

Proximity sensors |

Touch-free access to selected functions |

|

Temperature sensor |

Avoid exceeding the boiling point during drying |

|

Drying process visualisation |

Determine the changes characteristics of mass loss occurring in a sample during drying process |

|

4 drying process finish modes: manual, automatic,time-defined and user-defined |

Full adjustment of the process finish mode |

|

Easily removable elements and a rounded shape |

Easy to clean |

|

Specially designed drying chamber |

Its design shifts the dew point during evaporation, eliminating errors resulting from this phenomenon |

|

Extra sample of sodium chloride 10% (free of charge) |

Verify operation correctness of the moisture analyzer |

Why the PMV 50 PLUS Microwave Moisture Analyzer by RADWAG?

To answer your question, we have made some comparisons:

|

Drying method |

Convection drying |

Infrared (IR) drying |

Microwave drying |

|

Device |

Oven dryer |

MA 50/1/X2.A Moisture analyzer

|

PMV 50 PLUS Microwave moisture analyzer

|

|

Drying time |

approx. 3 h |

approx. 8 min |

approx. 3 min* |

All in all, if you are looking for the fastest and most precise drying possible, the PMV 50 PLUS microwave moisture analyzer is the device that will meet your requirements.

The PMV 50 PLUS RADWAG Microwave Moisture Analyzer - Intended Use

The PMV 50 PLUS RADWAG Microwave Moisture Analyzer - Intended Use

The PMV 50 PLUS microwave moisture analyzer is suitable for all applications where there is a need to dry materials containing significant amount of water. A device that guarantees such fast drying is ideal for laboratories, production lines and quality control, where time is of the essence. In order to check the water content of a product batch that is currently on the conveyor belt, it is necessary to act as quickly as possible and to react immediately if the results exceed the standard. For this reason, the PMV 50 PLUS microwave moisture analyzer is highly valued in industry, for example:

- cosmetics (e.g. for drying creams and lipsticks),

- chemical (e.g. for drying adhesives and detergents),

- food (e.g. for drying dairy and meat products)

and in sewage treatment plants for pre-press and post-press sediment analysis.

The PMV 50 PLUS RADWAG Microwave Moisture Analyzer – I'm Buying It!

Remember: time is money. The PMV 50 PLUS microwave moisture analyzer reduces the drying time of your products so you can save money. How?

Firstly, with the PMV 50 PLUS microwave moisture analyzer, the time from sample preparation to obtaining a result is relatively short, which results in minimized operation costs. Furthermore, sample preparation takes place without the involvement of additional materials such as reagents - only glass fibre filters are required. Such filters are widely available and inexpensive, and we add 50 free to every PMV 50 PLUS microwave moisture analyzer. What's more, if you buy this product, we can develop drying parameters on the PMV 50 PLUS for five of your samples. On request, we will also validate the drying method, i.e. we will determine the best way of working with the device specifically for you and prepare the relevant documentation.

What's more? The PMV 50 PLUS microwave moisture analyzer allows you to supervise your databases and facilitates data transfer to Excel - so you don't need to invest in additional tools for database creation and data transfer. Additionally, while purchasing our device you will receive free PC software (R-LAB) and the possibility to work using dedicated program - E2R Moisture Analyzers.

Are you interested in buying?

If you want to know more, visit our website or ask our expert: