What Requirements Must Weighing Devices Comply with to Be Used in an Ex Area? Scales for Ex Areas by RADWAG

An explosive atmospheric zone is an extremely harsh working environment, so it requires equipment that meets specialized safety procedures. All of these devices must be labeled “Ex,” but that’s just the beginning.

What Is a Hazardous Area?

A potentially explosive zone, or Ex area, is a space where there is a risk of a mixture of flammable substances in the form of gases, mists or dusts with air. An explosion occurs when the concentration of a flammable substance in a mixture with air is between the lower limit and the upper explosive limit. For it to occur, an oxidant (air), an ignition source and a combustible material are required.

There are several types of explosive zones, including zone 0, 1, 2, 20, 21 or 22.

Other potentially explosive zones apply to gases and liquids, while others apply to dusts, powders and fibers.

Potentially Explosive Zones for Gases and Liquids

Zone at risk of explosion 0 is an area in which an explosive atmosphere containing a mixture with air of flammable substances in the form of gases, vapors and mists occurs continuously or persists for a long time or frequently.

Zone at risk of explosion 1 is an area in which an explosive atmosphere containing a mixture with air of flammable substances in the form of gases, vapors and mists may occur during standard operation (periodically).

Zone at risk of explosion 2 is an area in which an explosive atmosphere containing a mixture with air of flammable substances in the form of gases, vapors and mists does not occur during standard operation, and if it does occur, it persists for a short period of time.

Explosive Atmospheres for Dusts, Powders and Fibers

Explosive zone 20 is an area where an explosive atmosphere in the form of a cloud of combustible dust in the air persists continuously, frequently or for long periods.

Explosive zone 21 is an area where an explosive atmosphere in the form of a cloud of combustible dust in air may occasionally occur during standard operation.

Ex zone 22 is an area where an explosive atmosphere in the form of a cloud of combustible dust in air does not occur during standard operation, or if it does occur, it persists for a short period of time.

RADWAG Scales for Ex Areas

Although an explosion-prone area is a particularly demanding working environment, RADWAG offers scales dedicated precisely to Ex areas.

Our scales are prepared for operation in explosion hazard zones 1 and 2, as well as 1/21 and 2/22.

The HX5.EX Scales will prove themselves at work in gas explosion-prone areas, classified as zones 1 and 2. They are ATEX-certified and GLP-compliant. You can choose from a myriad of models, depending on the required accuracy (0.1 g – 2,000 g) and optimal load capacity (1.5 kg – 6,000 kg).

Among them are:

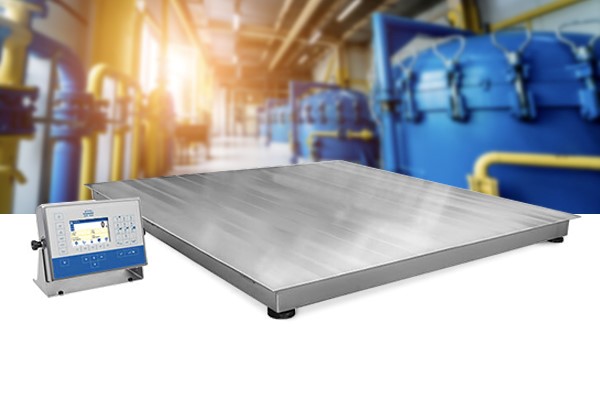

- Load-Cell Platform Scales in all-stainless steel version, i.e. waterproof HX5.EX-1 H, and HX5.EX-1 C made of stainless steel and powder-coated steel,

- HX5.EX-1.4 C Load-Cell Platform Scales, which allow accurate weight measurement regardless of where the load is placed on the platform,

- HX5.EX-1.4 H/Z Stainless Steel Platform Scales that calculate the weight of a vehicle, vehicle with load and/or load without vehicle,

- HX5.EX-1.4P C Pallet Scales,

- HX5.EX-1.4P2 C Beam Scales,

- HRP EX Platforms.

We also have HX5.EX Scales dedicated to work in gas and dust explosive and dusty areas, classified as zones 1/21 and 2/22. Depending on the model you choose, their accuracy ranges from 0.1 g to 2,000 g, and the load capacity – from 3 kg to 6,000 kg.

If you work in zones 1/21 and 2/22, you will certainly be interested in:

- HX5.EX-1 HR Stainless Steel 1-Load-Cell Platform Scales,

- HX5.EX-1.4 H Stainless Steel 4-Load-Cell Platform Scales,

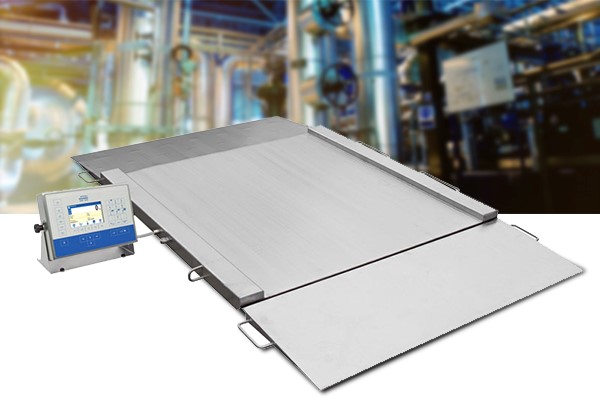

- HX5.EX-1.4N Stainless Steel Ramp Scales,

- HX5.EX-1.4P H Stainless Steel Pallet Scales,

- HX5.EX-1.4P2 H Stainless Steel Beam Scales,

- HRP EX.H Stainless Steel Platforms.

We can also offer you PUE HX5.EX Indicator, Ex-Scale-Intended Intrinsically Safe Power Supply for PUE HX5.EX Weighing Terminal and IM01.EX-8 Communication Module to increase the number of interfaces of HX5.EX indicator.